Introduction

This post answers following frequently asked questions:- What are the types of fits in engineering explain with figures & examples?

- How many types of fits are there?

- Different types of fits in mechanical & metrology?

- Different types of fits and tolerances between mating parts?

- Fits for shafts, holes, bearings, parts & machine drawing gd&t

Why do we need different types of fits in engineering?

In an assembly of two parts, it is important to look at how they mate with each other to ensure their proper utilization to achieve final results. To control how two parts mate with each other in an assembly engineer defines the degree of tightness i.e type of fit.

Take gear and a shaft for example. In this case,

- Gear should slide along the shaft parallel to the keyway. (Sliding fit)

- Gear should locate accurately. (Location fit)

|

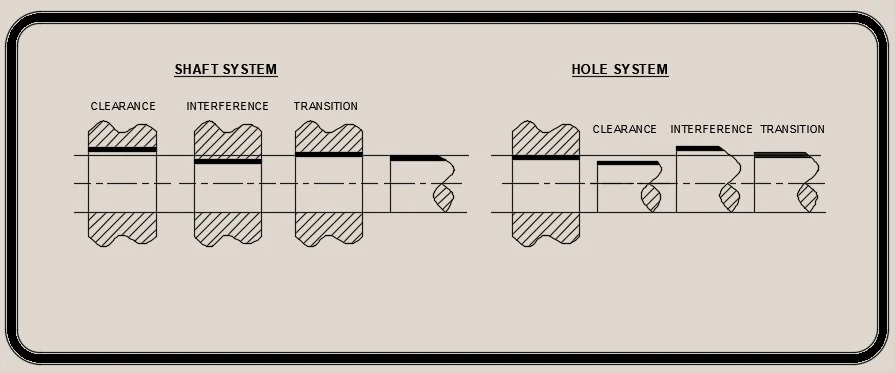

| 3 types in Shaft system & Hole system |

Fastening parts with improper fit will only tighten the parts and in some cases, you can even make it work as you wanted it to perform, but in the long run, it will fail for sure.

In engineering terms, the Fit is the degree of tightness or looseness between the mating parts.

Different types of fits in engineering

The Fit is classified into 3 types they are,

- Clearance Fit

- Interference Fit

- Transition Fit

Clearance Fit

A Clearance fit exists if,

- There is a gap between the joining components. That means the diameter of the shaft is always smaller than that of the hole.

- The tolerance zone of the hole will be above that of the shaft.

- We can calculate the maximum and minimum clearance from the formula given below.

Maximum clearance = Largest hole diameter - Smallest shaft diameter

Minimum clearance = Smallest hole diameter - Largest shaft diameter

For example, a block of a size that varies from 60.10 mm to 60.40 mm goes into a step having a size from 60.50 mm to 60.70 mm. Here, the values can be obtained as follows,

Maximum clearance = 60.70 - 60.10 = 0.60 mm

Minimum clearance = 60.50 - 60.40 = 0.10 mm

For instance, let's say after machining we get a block of 60.25 mm and step of 60.75 mm then clearance will be 60.75 - 60.25 = 0.55 mm.

A clearance fit further divided into the following,

- Slide fit

- Easy slide fit

- Running fit

- Slack running fit

- Loose running fit

Slide Fit

- The parts will not run freely.

- They can move & turn easily & locate accurately.

Example: Sliding gears, Shaft guiding.

Example fit: H11/c11

Easy slide fit

- It will have minimum clearance.

- It is generally used where there is slow motion or irregular motion.

Example: lathe spindles

Example fit: H9/e9

Running fit

- Comparatively more clearance will be seen in a Running fit.

- Generally used for couplings and gear assemblies.

Example: Gears & couplings

Example fit: H9/d8

Slack running fit

- This fit is widely used.

- It is characterized by large clearance.

Example: Oil seals in a metal block

Example fit: H8/c11

Loose running fit

- Used for rotations at high speeds.

- Used for loose pulleys & gland seals.

Example: Sleeve bearings with low RPM.

Example fit: H9/d10

Interference Fit

The interference fit is further divided into 3 types, they are,

- Force fit

- Tight fit

- Shrink fit

Transition Fit

The transition fit is classified into 2 types.

- Wringing fit

- Push-fit

No comments:

Post a Comment