In this article, you will read about,

Introduction to rivets

Types

Advantages

Disadvantages

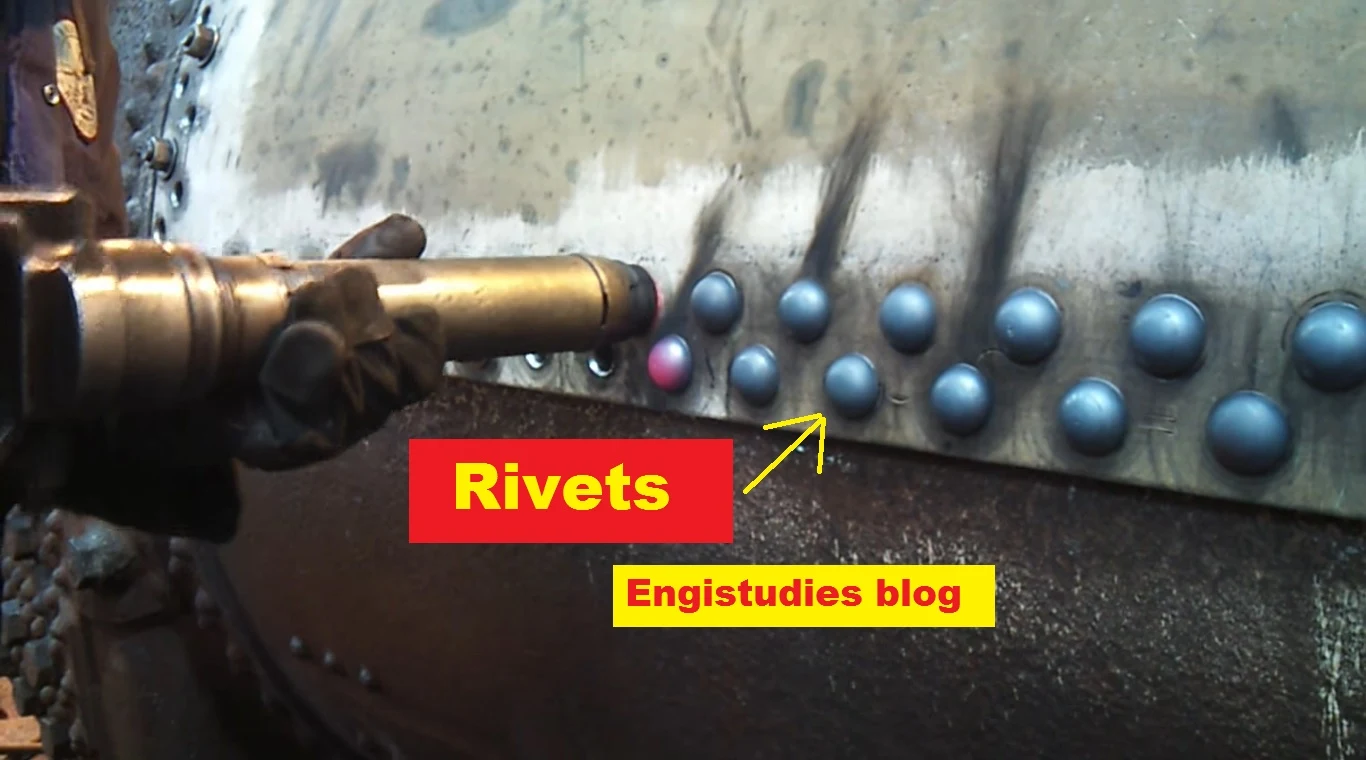

A rivet is a fastener consisting of a tail and a head at one end. It is a permanent type of mechanical joint. The tail is a simple cylindrical shaft with a circular cross-section.

It is used to join two or more plates using the hole in plates. During the joining process the tail end, opposite to the head end, is expanded. This creates a permanent strong joint. Tensile and shear stress act upon it after installation. This joining process is known as 'riveting'.

You can see the following types of image above,

Out of these types, round head is the strongest one and used most often.

Introduction to rivets

Types

Advantages

Disadvantages

A rivet is a fastener consisting of a tail and a head at one end. It is a permanent type of mechanical joint. The tail is a simple cylindrical shaft with a circular cross-section.

It is used to join two or more plates using the hole in plates. During the joining process the tail end, opposite to the head end, is expanded. This creates a permanent strong joint. Tensile and shear stress act upon it after installation. This joining process is known as 'riveting'.

|

| Rivets |

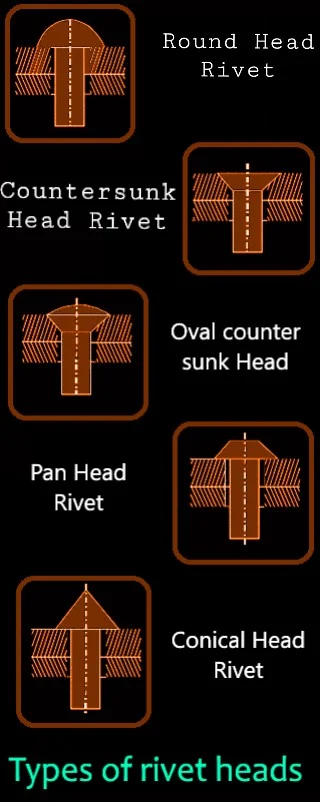

Types of rivets

We can classify them as below according to the shape of the head, |

| Different types of rivet heads |

You can see the following types of image above,

- Roundhead

- Countersunk head

- Oval countersunk head

- Pan head

- Conical head

Out of these types, round head is the strongest one and used most often.

Types of riveted joints

Lap Joints

When one plate overlaps the other to form a riveted joint it is called 'lap joint'. We can use single or multi-row of rivets as per our need.Butt Joints

In this type, the two plates to be joined are butt aligned with straps on one/both sides.Both the lap and butt joints can be divided futher according to,

- Number of rows they can be single riveted or double riveted.

- The distribution they can be chain or zig-zag type.

- The number of cover plates, only in case of butt joint, they can be single or double straps.

Advantages of riveted joints

- They can be used in case of non-ferrous metals like aluminum alloy, copper, and similar examples.

- One can easily inspect riveted joints.

- A riveted joint works better than any other method in environments with lots of vibrations and impact forces.

- They also give the best results for non-metal like some types of plastics and asbestos sheets.

Disadvantages of riveted joints

- High labor cost.

- The process of joining involves hammering and lots of noise issues.

- Riveting involves more labor and time than welding.

- Riveted assemblies are not tight and leak proof.

- More material cost.

- They are bulkier than welded joints.

- The high-stress concentration at holes on plates.

No comments:

Post a Comment